|

|

Enhanced Self-Priming Pump

UPM, UPS types (PAT.)

Suction and transfer of liquid containing foam or high viscosity liquid

|

|

|

The YOKOTA Enhanced Self-Priming Pump is a volute pump with an interlocked

water-air separating impeller and a vacuum pump.

The mixture of water and air gathered in the center of the volute pump

is centrifugally separated by rotation of the water-air separating impeller

and only the air is drawn out by the vacuum pump. Therefore the volute

pump always operates under the highest vacuum condition, and shows stable

and supreme pumping performance without being blocked by the incoming air

or cavitation.

It is probably the only horizontal shaft type volute pump in the world

which is capable of continuous suction and transfer of liquids containing

high viscosity sediment materials and air (i.e., gas-solid-liquid multiphase

flow).

|

UPM type:

|

Vacuum pump built-in type

|

|

UPS type:

|

Vacuum pump mounted type

|

|

UPS type:

|

Vacuum pump separate type

|

Unique features

|

|

Capable of continuous suction and transfer of liquids containing high viscosity

sediment materials and air (gas-solid-liquid multiphase flow).

|

|

|

Universal pump which is also capable of continuous suction and transfer

of liquids containing solid, such as food materials, muddy water containing

gravel, and sewage containing empty cans.

|

|

|

Enhanced self-priming type which needs no priming even at initial operation

after installation.

|

|

|

The intake piping can be constructed in many ways such as with waved pipes

or across embankments, and so on.

|

|

|

Due to rational construction, the pump is highly reliable, maintenance

is easy, and economical automatic operation is possible.

|

|

|

A wide variety of materials are available, including FC, SCS and YOKOTA's corrosion and wear resistant special stainless steel casting (YST), to meet the needs of various kinds of liquid.

|

Principle (PAT.) ............ Try and see its excellent performance.

|

UPM type

|

|

|

|

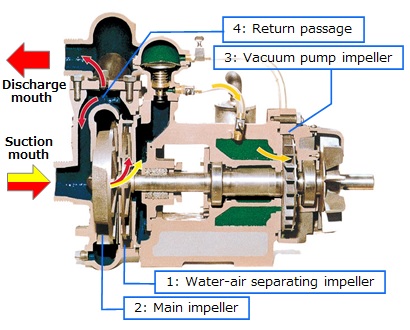

The water-air separating impeller 1 is installed between the volute pump

and the vacuum pump.

When operation is started, the main impeller 2 races and the vacuum pump

3 operates, eliminating the air in the suction pipe.

When the air is eliminated and a vacuum level close to the suction head

is reached, the pumping liquid flows into the pump casing, and is discharged

by the main impeller 2.

The mixture of water and air in the center is drawn by the vacuum pump

3, goes behind the main impeller and reaches the water-air separating impeller

1.

The water-air separating impeller separates the water from the air by centrifugal

force.

The water returns to the suction mouth through the return passage 4, and

only the air gathered in the center is drawn out by the vacuum pump 3.

Therefore the volute pump always operates under the highest vacuum condition,

and is not blocked by the incoming air at the pump suction mouth or the

main impeller. |

Applications

|

Transferring food materials:

|

Sauce, Soy sauce, Stock, Ketchup, Unrefined sauce, Liquor, Seaweed, Fluid

of other raw materials, other

|

|

Transferring chemical liquids:

|

Phosphate slurry, Formalin, Ammonia, Caustic soda, Light oil, Heavy oil,

Concentrated sulfuric acid, Ketone, Acrylic ester, Volatile liquids such

as ethylene glycol, Gas-containing liquid, Polypropylene powder, Pellets,

other

|

|

Loading and unloading for tankers:

|

Aniline, Nitrobenzene, Acetic acid, Nitric acid, other (cargo oil pumps

for cargo transfer and stripping for tankers, ballast pumps, bilge pumps)

|

|

Sludge drainage:

|

Sludge, Pulp waste water, Muddy water, Human waste, Pulverized coal sludge,

Sewage, other

|

|

Earth excavation:

|

Muddy sand, Seawater, Muddy water containing gravel, other (pumps for reverse

circulation, non-clogging dredging pumps, sand pumps)

|

|

Sealed (Vacuum) tank extraction:

|

Pure water, Chemical liquid, other

|

|

Defoaming air-containing liquid:

|

Foam latex liquid, Foam starch liquid, Normal paraffin fermenter liquid,

Lubricants, Hydraulic oil, Cutting oil, other

|

|

Other:

|

Hydropower snow transport (For details, please refer to "Current Topics: Snow Removal and Snow Melting".)

|

Example applications and installations

For transferring food material such as unrefined soy sauce

| Overview of the transport test |

|

|

|

|

Results of a comparative test on a diaphragm pump, vacuum tank pumping,

and the YOKOTA Enhanced Self-Priming Pump

|

|

The Enhanced Self-Priming Pump is the easiest to operate and is free of

problems caused by particles in unrefined soy sauce. It is also trouble-free

because the pump itself does not overload.

|

|

|

It has been recognized that some components in unrefined soy sauce are

changed during transport, and the Enhanced Self-Priming Pump and the diaphragm

pump have produced the best results in composition tests.

|

|

|

In soy sauce yield, the Enhanced Self-Priming Pump was the best, followed

by the diaphragm pump and the vacuum tank pumping.

|

(Based on results of a test conducted at a Hiroshima Food Testing

Facility)

For loading and unloading chemical liquids for chemical tankers

A chemical cargo pump that is used for loading and unloading chemical liquids

is generally equipped on the bottom of the ship, and therefore proves troublesome

when cleaning the tank or pump due to its location. With regards to safety,

it is far more convenient to locate the pump on the deck of chemical tankers

that handle toxic and volatile liquids.

The YOKOTA Enhanced Self-Priming Pump can be installed on the deck with

no problems whatsoever. If the pump is equipped on the deck, it is safe

and easy to perform the work when dealing with toxic liquids.

|

|

|

Layout with the pump equipped on the deck

|

The Enhanced Self-Priming Pump in operation

|

|

|

|

It can be installed on the deck.

|

|

|

It can substantially improve the efficiency of loading and unloading work.

|

|

|

It is safe.

|

|

|

The sweeping operation can be performed, and suction can be maintained

until the bottom of tank is visible.

|

|

|

Maintenance is easy and economical.

|

For defoaming lubrication, hydraulic, cutting, and other oils

Removal of air bubbles from lubrication, hydraulic, cutting, and other

oils is normally time consuming and costly. However, the YOKOTA Enhanced

Self-Priming Pump can perform defoaming work quickly and easily.

The outstanding feature of the Enhanced Self-Priming Pump is a defoaming

mechanism that works in unison with the normal pumping operation to provide

time and cost savings.

Example of a bearing lubrication circulation pump for hydraulic power generating

turbines

|

|

|

|

Pump discharge side

|

Comparison of pump suction and

discharge sides(Suction side on the

right, discharge side on the left)

|

Enhanced Self-Priming Pump

in operation

|

|

Bearing lubrication oil for hydraulic power generating turbines is circulated

for reuse. The Enhanced Self-Priming Pump provides circulation pressure

while also removing air bubbles trapped in the lubrication oil (defoaming).

Lubrication oil that enters the suction side of the pump has a large amount

of air mixed into it, giving it a cloudy appearance. However, when it is

discharged from the pump, defoaming has been performed to completely remove

any air bubbles, and the oil becomes transparent as can be seen in the

above photos.

This clearly demonstrates the tremendous effectiveness of the Enhanced

Self-Priming Pump for maintaining lubrication oil performance.

|

|

Besides lubrication, hydraulic, and cutting oils, the pump can be used

for defoaming in a wide variety of areas such as liquid foodstuffs, beverages,

chemicals, pulp, and waste liquids.

|

|

|

Since this pump provides both self-priming and pressurizing capabilities,

costs are greatly reduced because all processes, including suction, defoaming,

and pressurized transfer of liquid, are provided by this single, compact

pump, unlike conventional methods which require installation of several

components.

|

|

For draining sludge from rainwater settling basins at sewage facilities

|

|

|

|

|

UPS type pump at a sewage-treatment plant |

|

|

Good for environmental protection of rivers, and reducing smells emanating

from settling basins, other.

|

|

|

By draining stored septic water in rainwater settling basins into waste

water basins, pollution at the sewage facilities can be prevented. Flooding

can also be prevented by effectively using rainwater settling basins as

rainwater ponds.

|

For pumping out bored earth and sand in the reverse circulation construction

method

During underground excavation in the reverse circulation construction method,

instead of raising and lowering buckets, boring is continuously done using

drill bits, earth and sand are then discharged using circulating water

through the drill pipe.

The YOKOTA Enhanced Self-Priming Pump is being widely used as a suction

pump to pump out the bored earth and sand.

|

|

|

|

|

Bridge pier construction above river

|

The Enhanced Self-Priming Pump

in operation

|

|

|

|

The mud, sand and earth siphoning main pump is connected directly to the

vacuum pump to discharge air mixed in the pump. Both are set up on a base

plate with all the necessary equipment in a modular design that facilitates

transfer to the construction site.

|

|

|

As for conventional pumping devices used in the past for the reverse circulation

construction method, mud, sand and earth penetrating the vacuum pump caused

damage or stopped pumping. However, mud, sand and earth do not penetrate

the YOKOTA Enhanced Self-Priming Pump due to its built-in water-air separating

impeller. As a result, assured, continuous suction operation is possible

without breakdown or pump stoppage.

|

|

|

Its compact size requires half the installation area of conventional reverse

circulation construction method pumping devices.

|

|

|

Structure

UPM type

|

Part name

|

Part name

|

Part name

|

|

1

|

Pump casing

|

8

|

Bearing bracket

|

15

|

Discharge valve case

|

|

2

|

Partitioning plate

|

9

|

Gland

|

16

|

Discharge valve rubber ball

|

|

3

|

Rear plate

|

10

|

Gland packing

|

17

|

Shaft

|

|

4

|

Main impeller

|

11

|

Air suction and exhaust case

|

18

|

Air suction valve

|

|

5

|

Water-air separating impeller

|

12

|

Air suction and exhaust valve plate

|

19

|

Air suction pipe

|

|

6

|

Return passage

|

13

|

Ball bearing

|

20

|

Pressure pipe

|

|

7

|

Stuffing box

|

14

|

Vacuum pump impeller

|

|

|

|

|

Combination with vacuum pump

|

|

Vacuum pump built-in type (UPM10-S, UPM10-N)

|

|

The main volute pump and the vacuum pump are installed on the same axis.

|

|

|

Colorless, odorless, harmless edible oil is used as circulating liquid

in the vacuum pump.

|

|

|

Circulating liquid should be supplemented when it is under the marked level

on the level gauge.

|

|

|

Install a check valve on the discharge pipe to prevent suction of air from

the discharge side when the pump is first started. UPM10-0510S is equipped

with a discharge ball valve (check valve) as a standard accessory, so the

pump can be used by simply connecting hoses.

|

|

|

Vacuum pump mounted/separate types (UPS-N)

|

|

The vacuum pump is separated from the main volute pump (mounted type and

separate type).

|

|

|

Ordinary water (city water and industrial water) can be used as circulating

liquid in the vacuum pump.

|

|

|

Circulating liquid should be supplemented when it is under the marked level

on the level gauge.

|

|

|

Fill with circulating liquid up to the level above the vacuum pump's axis

when starting the pump for the first time.

|

|

|

Install a check valve on the discharge pipe to prevent suction of air from

the discharge side when the pump is first started.

|

|

|

It is possible to change the capacity of the vacuum pump if the pumping

liquid contains much air or the intake piping is long.

|

|

|

Circulating liquid may discharge from the supply tank. This is not a malfunction

and is caused by any of the following reasons.

|

|

1.

|

Too much circulating liquid: Lower it to the level gauge position.

|

|

2.

|

Circulating liquid is removed by the air: The circulating liquid discharge

amount will decrease as the exhaust air amount decreases.

|

|

Using this enhanced self-priming method, numerous kinds of transport equipment

using suction pumping can be accomplished.

|

|

Selection chart & Outer dimensions

Vacuum pump built-in type UPM10-0510S Direct drive type / Belt drive type

/ Dolly type

Vacuum pump built-in type UPM10-N (Direct drive, Non-clog type)

Vacuum pump mounted type UPS-N (Direct drive, Non-clog type)

Vacuum pump separate type UPS-N (Belt drive, Non-clog type)

Specifications stated here may be subject to change without notice due

to product improvement. |

|

>Back to Top |

|

|